Gear Motors

Our goal is to deliver gear motors that perform consistently, meet industrial standards, and support long-term operations.

Gear Motors Supplier in Pakistan

MV Power Drive supplies high-performance gear motors designed for industrial automation and power transmission systems across Pakistan. Our gear motors deliver controlled speed, high torque, and reliable operation for demanding industrial applications.

We offer industrial gear motors that combine electric motors with precision gear units to reduce speed and increase torque efficiently. These systems support smooth operation, reduced energy loss, and longer equipment life in continuous-duty environments.

Our gear motor solutions serve industries such as manufacturing, material handling, packaging, conveyors, mixers, and processing plants. We help clients select the right gear motor based on load capacity, speed requirements, duty cycle, and installation conditions.

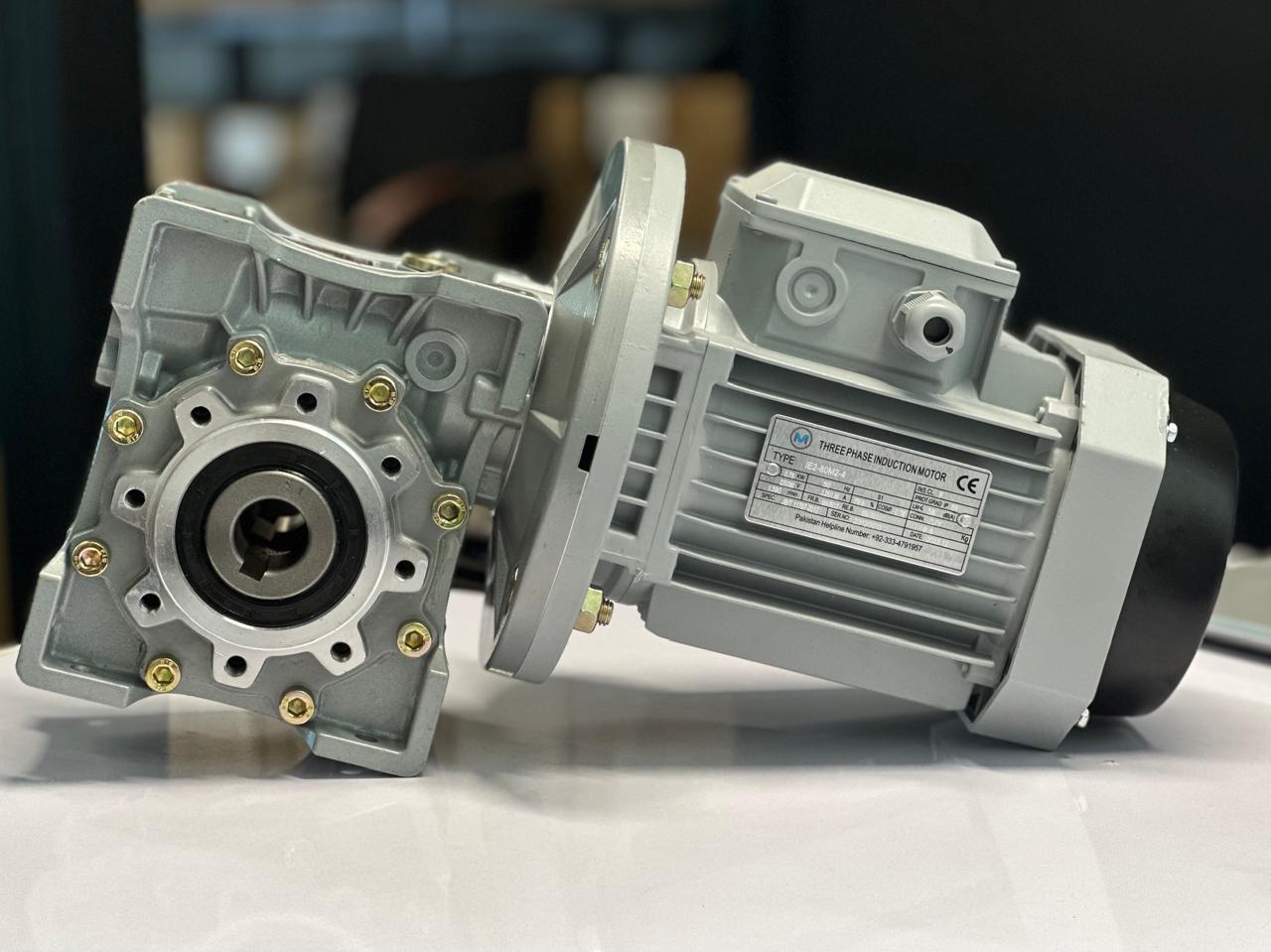

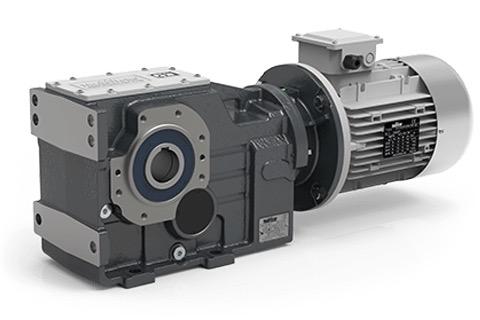

MV Power Drive provides worm gear motors and helical gear motors that meet industrial performance standards. Each solution supports stable output, low maintenance, and consistent performance under heavy workloads.

Our technical team assists with gear motor selection, application matching, and system compatibility to ensure reliable and efficient operation.

Available Gear Motor Types

- Worm gear motors for high reduction ratios

- Helical gear motors for smooth and efficient transmission

- Gear motors for conveyor and material handling systems

- Compact gear motors for space-limited installations

Industries Served

- Manufacturing units

- Packaging lines

- Conveyor systems

- Textile machinery

- Processing plants

How Gear Motors Improve Industrial Performance

Gear motors play a critical role in industrial systems that require controlled speed and high torque output. By integrating a motor with a gear unit, these systems reduce speed while increasing torque efficiently. This setup improves machine stability, reduces wear, and supports continuous operation in demanding environments.

Industries rely on gear motors to handle heavy loads, frequent starts, and long operating hours. Correct gear motor selection reduces power loss, improves energy efficiency, and extends equipment lifespan.

Gear Motor Selection Guidance

Selecting the right gear motor depends on several technical factors:

- Required output torque

- Operating speed and reduction ratio

- Load type and duty cycle

- Mounting position and space limitations

- Environmental conditions

Our technical team assists in selecting gear motors that match application requirements and ensure safe, efficient performance.

Why Industrial Buyers Choose Our Gear Motors

These advantages help reduce downtime and operating costs.

- Stable torque output under heavy load

- Smooth speed control for automation systems

- Durable construction for long operating hours

- Low maintenance requirements

- Compatibility with industrial control systems

Looking for Gear Motor & Drive Solutions?

Reach out to our team in Lahore for performance-driven products, expert guidance, and fast delivery across Pakistan.

Fast Delivery

We have most of the things in stock so can provide fast delivery. Incase of specific demands we can arrange in very short period of time.

Best Quality

We work with the quality producing manufacturers globally and continuously keeps on updating with new technical innovations with time.

Free Return

Enjoy peace of mind with our free return policy. if you’re not completely satisfied, We make the process quick, easy, and hassle-free for your convenience.

FAQs

How do I choose the right gear motor?

Gear motor selection depends on required torque, operating speed, load type, duty cycle, mounting position, and working environment. Technical guidance ensures correct selection and reliable performance.

What types of gear motors are available?

Common types include worm gear motors for high reduction ratios and compact design, and helical gear motors for smooth operation, high efficiency, and continuous-duty applications.

Can gear motors work with variable frequency drives?

Yes. Gear motors work efficiently with variable frequency drives to control speed, reduce energy consumption, and improve system flexibility in industrial automation setups.

Are gear motors suitable for heavy-duty applications?

Yes. Industrial gear motors are designed to handle heavy loads, frequent starts, and long operating hours when selected correctly for the application.

Do you provide technical support for gear motor selection?

Yes. Our technical team assists with gear motor selection, application matching, and system compatibility to ensure safe and efficient operation.

Does MV Power Drive provide after-sales support?

Yes, we provide complete after-sales support, including technical guidance, motor installation advice, and maintenance recommendations.

Are Your Products Are Original And Covered By Warranty?

Yes. All our gear motors, reducers, and VFDs are 100% genuine and come with manufacturer warranty and full after-sales support.

Where is MV Power Drive located?

We are based in Lahore, Pakistan, and supply electric motors and drive systems to clients nationwide through reliable delivery and support channels.